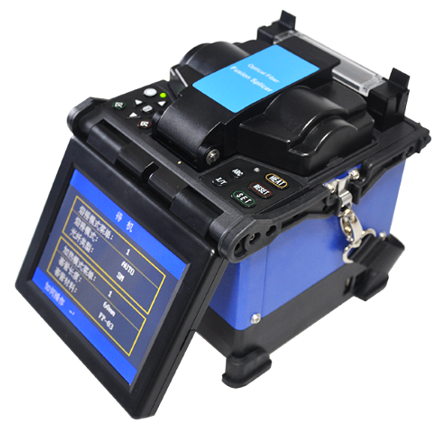

An optical fiber splicer is a device that uses an electric arc to fuse the ends of two optical fibers together to form a long optical fiber. The resulting joint, or fusion joint, permanently connects the two glass fibers end to end, so that optical signals can travel from one fiber to the other with minimal loss.

How does the welding machine work?

Before the fibers can be successfully fused, their coats and polymer coatings need to be carefully peeled off, cleaned thoroughly, and then cut precisely to form smooth, vertical ends. After all this is done, each fiber is placed into a bracket of the adapter housing. From this point, the fiber splicer takes over the rest of the process, which consists of 3 steps:

Alignment: The splicer uses small precision motors to fine-tune the fiber positions until they align correctly, so the final splicing is as seamless and attenuation-free as possible. During the alignment, optical fiber technicians can observe the alignment of optical fibers by amplifying the optical power meter, camera, or viewing lens.

Impurity burn: Since the slightest dust or other impurities can seriously affect the splice head's ability to transmit optical signals, you can't be too clean when performing a fusion. Although the fibers are manually cleaned before they are inserted into the splicing device, many splicing machines incorporate an additional preventative cleaning step into the process: Before splicing, they create small sparks between the fiber ends to burn off any residual dust or moisture.

Fusion: After the fibers have been positioned correctly and any remaining moisture and dust has been burned off, it is time to fuse the ends of the fibers together to form a permanent splice. The splicer emits a second, larger spark that melts the end of the fiber without causing the fiber cladding to fuse with the molten glass core (keeping the cladding and core separate is critical for good splicing to minimize optical loss). The fused fiber tips are then joined together to form the final fusion. An estimated splicing loss test is then performed, and the typical optical loss for most fiber fusion joints is 0.1 dB or less.

04-08

202404-07

202403-26

202403-26

202403-18

202403-18

202403-13

202403-11

202403-11

202403-07

2024