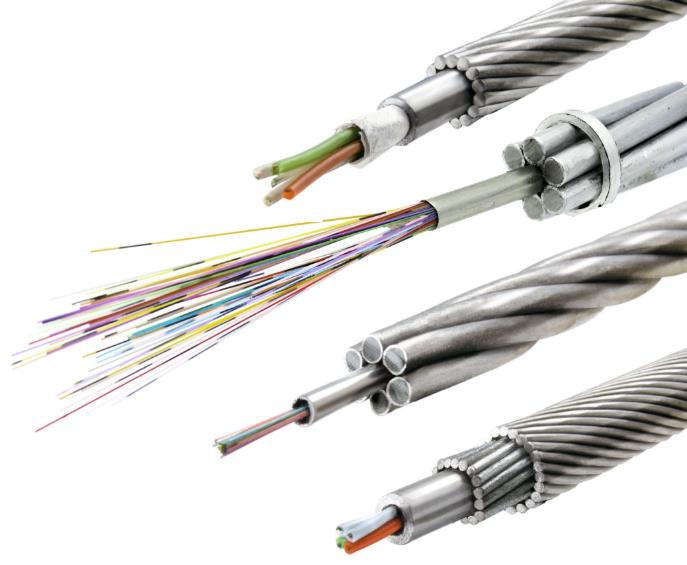

Optical fiber composite overhead ground wire OPGW has high reliability, superior mechanical properties, low cost, and is more economical to install or replace the existing ground wire. On the basis of analyzing the structure and application characteristics of OPGW optical cable, the author expounds the common method of OPGW optical cable erection, and analyzes the key points of construction control, such as laying out, laying out, installation of supporting equipment, and disposal of residual cable, and points out the matters that should be paid attention to in the installation process, which has practical engineering guiding significance.

1 Introduction

OPGW cable, also known as optical fiber composite overhead ground wire. The optical fiber is placed in the ground wire of the overhead high-voltage transmission line and installed on the top of the transmission line tower to form the optical fiber communication network on the transmission line. This kind of structure has the dual functions of ground wire and communication, generally known as OPGW cable.

OPGW cable is wrapped with metal wire, so that the cable is more reliable, stable, firm, because of the overhead ground wire and cable composite as one, compared with the use of other ways of cable, not only shorten the construction period and save construction costs. In addition, if the use of aluminum clad steel wire or aluminum alloy wire stranded OPGW, equivalent to the erection of a good conductor overhead ground wire, can be received to reduce the power line latent supply current, reduce power frequency overvoltage, improve the power line interference and dangerous influence on the communication line and other benefits.

OPGW is suitable for high voltage more than 110kv line, the file distance is larger (generally above 250M); Easy to maintain, easy to solve the problem of line crossing, its mechanical characteristics can meet the line crossing; The outer layer of OPGW is metal-armored, which has no effect on high voltage corrosion and degradation. OPGW must be cut off during construction, and the loss of power outage is large. Therefore, OPGW should be used in the newly built high-voltage lines above 110kv. Fiber material for glass fiber, easy to break, relatively fragile.

During the construction process, OPGW should be prevented from being pulled, bruised, sprained, crushed and broken, and the cable should be smooth traction without being squeezed basically.

2 tension pay-off method of OPGW cable construction

(1) tension pay-off method

OPGW commonly used wiring method recommended for tension pay-off method, tension pay-off method is through tension equipment, OPGW in the whole process of pay-off by a certain constant tension, to ensure that there is enough gap with obstacles and other objects, avoid friction, and will not damage OPGW, at the same time can reduce the compensation of green plants, reduce physical labor and improve the construction progress.

(2) OPGW cable construction based on tension pay-off method

1) Guide cable laying

OPGW cable from the top into the tension machine wheel, around the tension wheel after 6 laps, from the top out. With traction mesh sleeve connector fixed ground wire leading end, 30kN rotary connector will guide rope and traction mesh sleeve connection (connecting cable should pay attention to check whether the cable type and left and right ground support corresponding)

Lead the front end of the guide rope into the winch wheel from above the tractor, wind the winch wheel for 6 laps and then lead to the guide rope tray from above. Install the ground block on the guide rope and OPGW cable. Zhang, pull field preparation work is completed, start traction should be slow traction, in the cable end connected with the detorsional device and traction mesh set, anti-torsional whip through the first base tower, if the situation is normal can gradually steadily increase traction speed to 30 meters/min.

When the joint of the guide rope (i.e. the 30kN bending connector) is drawn close to the tractor, the traction should be slowed down so that the joint slowly passes through the winch of the tractor.When the joint into the guide rope coil 2-3 turns, should suspend traction. The guide rope is anchored at the front of the tractor with a clamp. Untie the bending connector of the guide rope connector, remove the wrapped guide rope coil, and replace the empty guide rope coil.

The unloaded guide reel shall be sent to the designated place in the next payout section or recovered to the tool store in time according to the plan. Wrap the guide rope head around the empty disk and tighten it, start the tractor and pause again after the force is applied, remove the clamp, and then continue to pull. After the cable passes the last base tower, it should be sufficient for testing and continuation. The length reserved at the traction end is 1 tower height plus 10 meters.

Stop traction and anchor the front and rear ends of the cable to the ground anchor with a cable clamp. The ground of the anchor line should be connected with 30KN hand hoist and tightened to maintain the tension of the ground wire or traction rope. Remove the tow rope, and a process of cable traction is over.

2) Tighten the thread

Cable exhibition after release, should be carried out as soon as possible tight line construction. The tightening should be carried out during the day, and the weather should be free from fog, rain and wind. Select the observation file and the current temperature and wind speed according to the sag calculation table, and tighten the wire according to the tightening method of tension payout.

The operation of the tightening line is as follows: leave enough cable at the end of the anchor line, the length of the cable is the height of the tower plus 10 meters, and attach the tensioning clip to the side of the tightening line. The cable with only one tensioning section is the same as the common ground cable.

When multiple tensioning segments are connected without being disconnected, the tightening method from far to near should be adopted: That is, after a tension section furthest away from the tension line side, mark on the second base tension tower, and install the tension gold on the tight line side and hang the line, and then relax the tension on the tight line side, take out the pay-off block, one by one straight tower installation of dangling gold and grounding wire, and leave enough cable on the tension tower (1.2 times the width of the cross arm), Then install the tensioning clip on the side of the line to be tightened and hang the line, tighten the next durable tensioning section, and so on.

Note in the tightening process, OPGW cable surface to protect with rubber tube, so that it will not be wedge and tight line pulley operation scratch. Appropriate counterweight should be added during operation to prevent OPGW winding. And in the cable out of the tension line clamp with nylon rope tied to the hoist chain, so as to avoid excessive bending of the cable.

3) Observation and adjustment of radians

Tighten the temporary cable of the anchor line tower properly, so that the hanging point of the cross arm deflects 30 ~ 50mm to the opposite side of the force. Start the winch mill and tighten the OPGW. When the sag of the observation file is close to the design sag value, traction should be stopped, and the sag observation should be carried out after OPGW is stabilized until the design requirements are met

(a) Arcs observed by equal length method

Equal length method is parallelogram method. When conditions permit, equal length method should be preferred. FIG. 3 shows the arrangement of arcing observation with equal length method. When the arc is observed, the connection of the plane on the two arcs is tangent to the lowest point of the overhead line, that is to meet the design requirements.

(b) Arc observation by Angle method

In the tensioning section with large gap, the Angle method of theodolite can be used to observe, and the stop-end method is generally used to observe. FIG. 4 shows the schematic diagram of arc observation by Angle method. Its operation steps are as follows: determine the position of theodolite and check the height difference between it and the suspension point of overhead line of observation file; The observed Angle θ at different temperatures was calculated. Adjust the arc of the line so that the axis of the overhead line is tangent to the line of sight of the theodolite; Check the overhead line immediately after it is hung, and fill the observation results into the sag record sheet.

(4) OPGW supporting equipment and accessories installation

OPGW cable used in the erection and installation of the type of equipment usually static end (tensile) equipment, suspension (tangential) equipment, damper, wire bar, lead fixture, ground wire, intermediate connection box, terminal box, etc. In particular, it is emphasized that in the cable, cable, adjusting arc and tension must use OPGW cable special static end (tensile) hardware, so as to avoid OPGW cable damage.

In order to prevent vibration wear of the cable, the cable should not stay in the pulley for more than 48 hours after tightening the cable. Each set of tight-wire fittings can be reused up to three times depending on the operation condition. The fittings for permanent use in the project must be new.

3 OPGW installation quality control points

1) Erection of OPGW optical cable is similar to power line. When erection, the original transmission line must be operated with power failure. Construction is prohibited in severe climate such as strong wind, thunderstorm, cold and hot summer. The bending radius of the cable should be at least 0.5m.

2) In the construction of the cable to avoid entanglement together, to avoid damage to the cable stranded layer. The dynamic bending should not be less than 40 times the cable diameter, that is, the bending radius of at least 600mm should be ensured during construction, and the OPGW cable should not be twisted.

Special personnel shall be assigned to monitor the crossing of major traffic roads, communication lines and power lines. The cable must be controlled at a safe height to avoid motor vehicles colliding or rolling the cable, endangering the safety of the cable or personnel.

3) OPGW cable erection to the ground crossing distance requirements: unmanned area, OPGW off the ground more than 3 meters; Pedestrian road and sparsely trafficked road, OPGW above 5m; Highways and railways, OPGW above the ground 7.5m.

4) In the construction process, pay attention to the protection of the outer layer strand. The outer aluminum clad steel wire or aluminum alloy wire is the carrier of overcurrent and lightning strike, such as injury will have long-term risks to the line. To check the pulley for burrs; Do not throw, drop optical cable; Use rubber sleeve when using wire lifter. OPGW cable tray is placed on the pay-off rack or cable tray car with rotating shaft, cable tray and tension machine center distance should be guaranteed to have 5-8m.

5) Every day should ensure that the single disk cable construction is completed, if not overnight or long time placed, must use nylon rope OPGW cable fixed on the pulley, to prevent optical cable sliding and pulley contact point fiber fatigue damage. At the same time should be in traction end, tensile end of their respective traction rope, cable temporary anchorage. The relaxation degree of the cable between the anchor line point at the tension end and the tension machine is appropriate to remove the tension of the stretch machine. Not too slack, cable must not mop the floor.

4 Closing Remarks

Through the above OPGW cable characteristics and installation control points, the construction personnel can master the key issues of OPGW line construction, establish a concept of OPGW line construction process and quality control, has a positive guiding significance for engineering practice. However, more problems related to OPGW, such as the research on the cause of lightning breakage, are still in the exploration stage, so they need to be further explored and solved in the future.

04-24

202404-23

202404-23

202404-08

202404-07

202403-26

202403-26

202403-18

202403-18

202403-13

2024