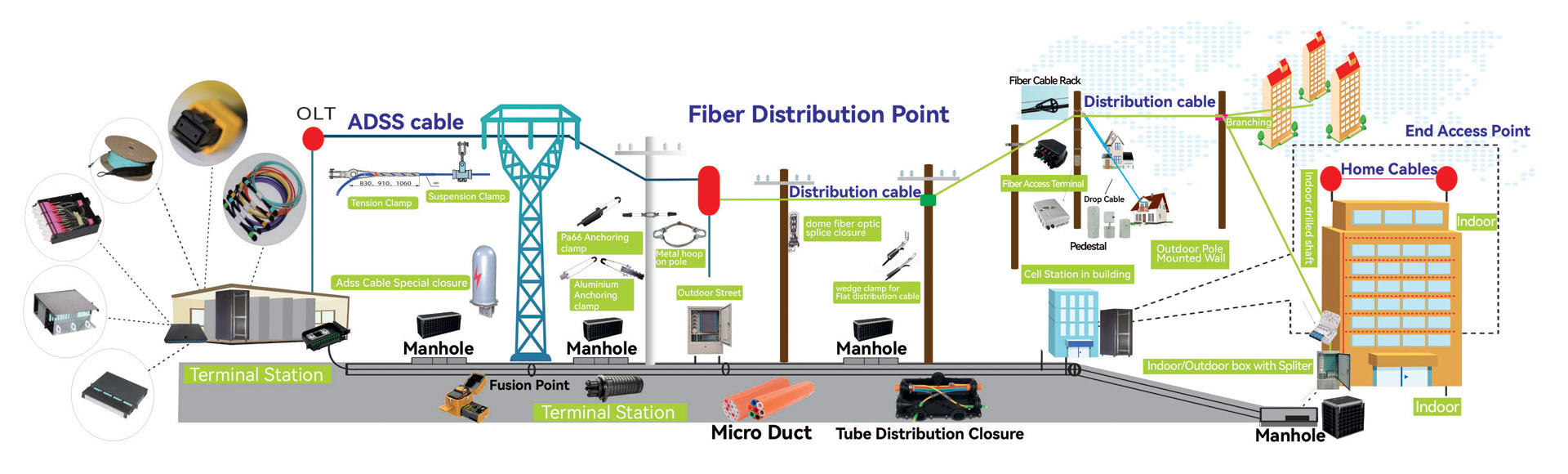

The use of communication optical cables is more adaptive laying of optical cables such as overhead, buried, pipeline, underwater, etc. The conditions of laying each optical cable also determine the different laying methods. The editor will tell you about the specific installation methods of various laying:

Aerial fiber optic cables are suspended from rods used in fiber optic cables. This laying method can use the original overhead Mingji Road, saving construction costs and shortening the construction period. Aerial optical cables are suspended on poles and need to adapt to various natural environments. Aerial optical cables are easily affected by natural disasters such as typhoons, snow and floods. They are also susceptible to external forces, and their mechanical strength is weakened. Therefore, the failure rate of aerial optical cables is higher than that of buried and ducted optical cables. Usually used for long-distance two or less lines, suitable for dedicated network optical cable lines or some local special parts.

There are two ways to install overhead optical cables:

1: Hanging type: hang on the pole with wires, and then hang the optical cable with a hook to hang on the optical cable, and the load of the optical cable is carried by the suspension wire.

2: Self-supporting: The optical cable adopts a self-supporting structure, the optical cable is in the shape of "8", the upper part is a self-supporting optical cable, and the load of the optical cable is carried by the self-supporting line.

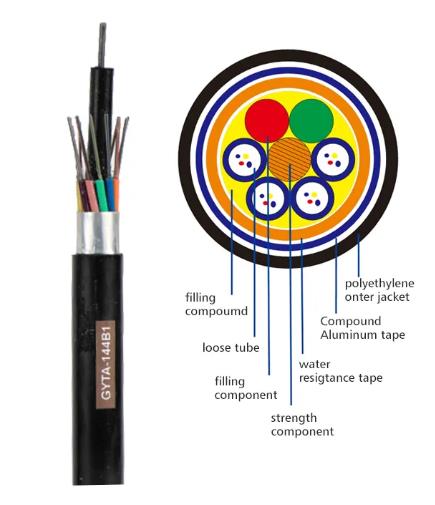

Buried optical fiber cable: External optical cable or steel wire armor, directly buried in the ground, requires resistance to external mechanical damage and soil erosion performance. Different protective layer structures are selected according to the use environment and conditions, for example, insects and rodents are in the area, used together with insect-proof ratchet sheathed optical cables. Depending on the soil and environment, the optical cable buried underground is generally between 0.8 meters and 1.2 meters. When laying, care must also be taken to keep the fiber strain within the allowable range.

Pipe laying is generally in urban areas, and the environment for laying pipes is better, so there are no special requirements for optical cable sheaths, and no armoring is required. Before laying the length of the lay section and the location of the connection points, the pipe run must be selected. Laying can use mechanical bypass or manual pulling. The traction force does not exceed the allowable tension of the optical cable. Pipe production can be selected according to the geographical conditions of concrete, asbestos cement, steel pipe, and plastic pipe.

The environmental conditions of underwater optical cable laying are much more serious than those of direct buried optical cables, and the faults and measures of repair technology are much more difficult. Therefore, the reliability requirements of underwater optical cables are also higher than those of direct buried optical cables. Submarine optical cables are also underwater optical cables, but the laying environment conditions are stricter than ordinary underwater optical cables, and the service life of submarine optical cable systems and components is required to exceed 25 years.

04-24

202404-23

202404-23

202404-08

202404-07

202403-26

202403-26

202403-18

202403-18

202403-13

2024